Modular Belt Conveyors

Modular belt conveyors are widely used across the food industry due to their versatility, hygienic design, and adaptability to complex production processes. They are suitable for a broad range of applications, including processing, cooling, packaging, and accumulation lines.

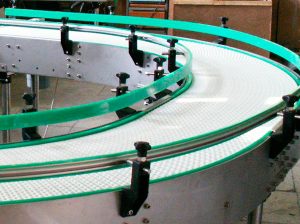

The conveyor belt consists of interconnected plastic modules assembled into rows and joined by hinge rods. This modular construction allows conveyor belts to be configured to virtually any width and length using standardized components. The design ensures high flexibility in layout while maintaining consistent operational performance.

A key advantage of modular belt conveyors is the simplicity of assembly, maintenance, and belt repair. Individual modules or sections can be replaced quickly, minimizing downtime and supporting efficient long-term operation. The modular structure also enables easy system modification or expansion as production requirements change.

Modular belt conveyors can be designed with complex conveying paths, including straight sections, curves, inclines, declines, and spiral configurations. This makes them an effective solution for optimizing product flow in space-restricted or technically demanding production environments.

Due to their hygienic properties, durability, and layout flexibility, modular belt conveyors represent a significant share of conveyor equipment used in modern food-processing facilities.