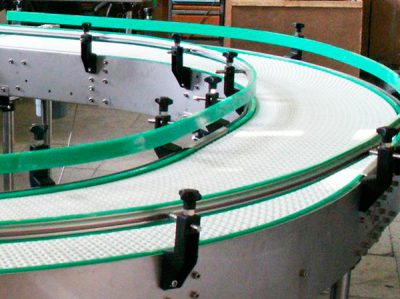

Curved Modular Conveyors

Curved modular conveyors are designed to create complex conveying paths while maintaining continuous, controlled product flow in food-processing environments. By eliminating transfer points, they reduce product handling, minimize contamination risks, and support stable line operation.

For food-industry applications, these conveyors are manufactured using food-grade modular belts and hygienic design principles. Smooth surfaces, open belt structures, and easy access for cleaning allow effective sanitation and visual inspection, supporting compliance with food safety requirements such as HACCP-based processes.

Curved modular conveyors enable the integration of straight and curved sections into a single conveying line, making them especially suitable for space-restricted layouts and complex production environments where product integrity and hygiene are critical.

Compared to straight conveyors, curved modular conveyors have a higher cost per meter. This is due to the use of specialized curved belts, more labor-intensive manufacturing processes, and the need for more powerful drive units to ensure stable belt movement under curved load conditions.

Despite the higher initial investment, curved modular conveyors offer long-term benefits through improved hygiene, reduced product transfers, and greater layout flexibility in food-processing lines.